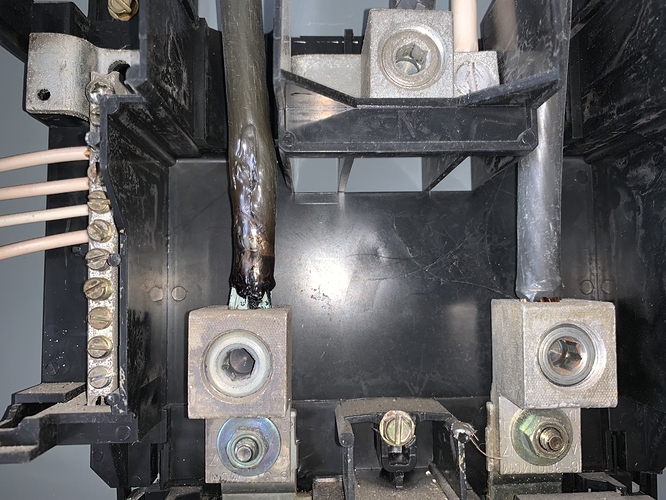

Looking for some insight on a defect. This Undegrounded SE Conductor has had obvious “overheating

issues”, either in the past or currently. And I know the SOP is to recommend further eval by a Qualified Electrical Contractor. But for my personal CE, what would cause this?..I am thinking Lighting Strike, but am curious as to a more technical opinion.

Thank You

Matt

Loose termination.

The termination may be loose, Matt.

Thank you Larry and Simon…always helpful with a timely and intelligent answer

can you expound a bit on why a loose connection between the Conductor and the Lug would cause this effect. Is the resistance a factor, and if so, how so?

thank you gentlemen

Matt

“Poor connections can be very efficient at overheating, because they can generate a high wattage over a small area for a long period of time. This is evidenced in the research from William J. Meese and Robert W. Beausoliel in the “Exploratory Study of Glowing Electrical Connections,” published by the National Bureau of Standards, and NFPA 921, the “Guide for Fire and Explosion Investigations” from NFPA. If the watt density is high enough, the connection will glow. An oxide actually forms at the (loose) contact area, and the resistance of the oxide causes the I2R power dissipation.”

Matt, when a conductor becomes loose in a lug it often arcs. Think when you build up a static charge and get close to a grounded metal surface (or another person) you get a spark. That spark is an example of the electrical arcing that has likely occurred at this termination. An electrical arc can create temperatures up to 35,000 degrees. While this termination is not likely at 35,000 degrees, the heat generated in the loose connection was enough to cause significant damage to the conductor and the conductors insulation. In your picture note the color differences in the conductor, the insulation, the lug, the lug screw etc… This has gotten REALLY hot.

Note the discoloration of the copper conductors. Yup.

Just for the hell of it Matt, could you see the panel’s ground wire connection.

If so, was it discolored or black.

someone called the mythbusters

Addition cause:

That’s the torque wrench I own

Good morning Marc

I will check pics for Ground Wire connection for discoloration. I seem to recall a post from you in the past about this subject. Is that GW discoloration an indication of a Power Surge/ Lighting Strike?

thanks as always

Matt

Yeah I was thinking lightning.

Here’s one near us on Pond Apple Road ![]() BLACK copper Ground Pic.pdf (223.8 KB)

BLACK copper Ground Pic.pdf (223.8 KB)

It could be loose as mentioned above, additionally I see no de-Ox on the wire where it is in contact with the lugs. This will cause the wire to oxidize thus becoming smaller in diameter and then the arcing will begin and bammm You have heat issues as noted in your picture.

jim

Just playing devil’s advocate here, but my first suspicion from the picture is that it was OVER-torqued, which broke some of the strands of the SE cable. That effectively makes it a smaller size cable, leading to overheating. (Same principle as trimming strands to fit it into a too small lug.) I’m basing my suspicion on the fact that the set screw is recessed into the lug fitting, rather than protruding slightly.

Torque specs are given for a reason, but hardly anyone actually uses a torque wrench. “Just tighten til it squeaks,” (but that’s too much.)

Thanks Marc. I was over that way yesterday, off of Verde Trail. Hope all is well

matt

Stab-Lok city in there… … …