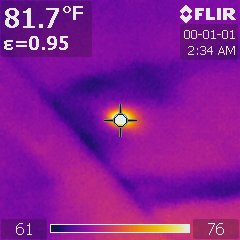

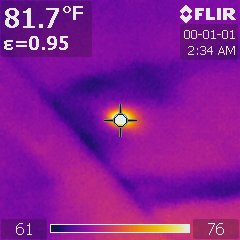

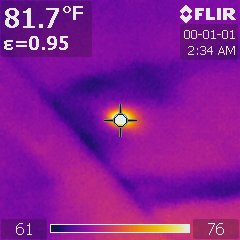

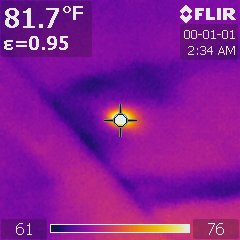

What do you guys think of this low voltage transformer temperature found in the attic sitting on the vapour barrier, gyproc. Are they suppose to run this warm?

What do you guys think of this low voltage transformer temperature found in the attic sitting on the vapour barrier, gyproc. Are they suppose to run this warm?

Yes.

There are IR programs for training concerning “standards”.

I would highly recommend that if you only attended a “Basic” IR course that you continue ( and cough up the bucks) with education and experience in IR.

99% of camera owners do not know what they are looking at.

Just don’t subscribe to that group.

David,

Why don’t you chill out! Mark asked for help not unsolicited advice from a know it all!

Frankly I’m getting tired of your posts lately. If you don’t want to help Mark then don’t bother posting.

For the record, I would venture to say that many Level I, II and III Thermographers may not know the answer to his question, which I believe is a very good one.

Keep 'em coming, Mark.

Kevin

Thanks Kevin,

We’re not all Mr. Know-It-Alls.

I know…previous post was kinda harsh ![]()

I’m tired and it’s been a long day…

Kevin

I’m also tired and had a long day.

Just go to bed Kevin!

If I am not mistaken Kevin, you promote the IR programs and standards I am referring to. Are you going to just hang around here with your level III training and answer these types of questions, hoping someone will find it some how in your words of knowledge? Just don’t be right too much, you’ll become a know-it-all.

I don’t know it all. I simply state “known facts”. If some of you want to make up crap as you go along that’s just fine.

If you don’t know the facts, there are places to get them.

If you think NACHI is a place to get it all for free, call Ben and he’ll make a video.

Know it all,?

I don’t make this stuff up.

I guess I need to screw up more and be part of the good ole boy club…

The fact of the matter is that many hvac and ir threads seem to end with my name.

No on seems to research anything and prove me wrong, so I just keep on, keeping on.

If you have proof, post it. What power do I have to keep you from disclosing the truth? I am always looking for something new to learn. Teach me something for a change.

I have posted time and time again, if you don’t know what your pointing your IR camera at, point it elsewhere. There are those of you out there that have a $5k imager, spent $$ on training (of sorts) and you haven’t yet pointed it at your cell phone charger and realized that transformers make a lot of heat?

In this case, just what building material has a flash point below 112 degrees F?

They say there are no stupid questions, some say stupid people ask questions, I say some questions are asked by lazy people.

In my opinion, if I were to pay someone $300 to check my house I think they should know what moisture looks like, what air infiltration looks like, what a hot electrical service is and is not. These things have specific signatures. Basic Level I.

GFIC’s, transformers, smoke detectors, motors, heating and a/c equipment generate heat due to the work they do. There ARE standards. Get them, learn them, then go do your job. If you don’t, you make all of those above us in this field look like fools and bring discredit upon the industry. Which is not an asset to anyone.

There are standards, and few of you are getting it.

Your not even paying attention to John M’s HI course. If you don’t invest in the training it means very little. Free advise here obviously means very little to many who blindly oppose. John told me that many take his two day course and never turn in the field assignment. Evidence to my point.

Contact jim@infraspection.com and others that have years on us and get with the program.

Ya’ll tired of my posts, well that can be remedied. I’m tired of your posts and we can call it even.

Mark, I apologize to you. This is not about you or your question. This is about complacency of those that should know better. You should have been taught the answer to your question. That is by beef.

I also apologize to the others; my trying to interpret the facts, trying to make a wild-*****-guess on minimal information, for getting frustrated when other know-it-alls (by interpretation) call overheated breakers, hundreds of times over the accepted standard as being “NORMAL”.

Yup,

I’m not one to kiss your ***** and make you feel good. I just want you to do the right thing by your customer and maybe keep your sorry butt out of court.

I’ll take my book of “know-it-all” and be gone.

Bye.

I appreciate your concern, I believe education is a valuable asset and yes I am Infrared-Certified. Although, I can never learn enough. What is your opinion of the heat from this transformer. It was located in a garage and the median temperature in my location this time of year is around 5 C or 41 F.

I guess, next time I could write the manufacturer information down and give them a call…

I just wanted some discussion on it ![]()

Ok, point taken, thanks.

Kevin I can understand David’s furstration (for a lack of a better word) some of us have absolutely spent thousands of dollars on the best training available (our choice) and when someone that comes on line with $150.00 worth of training wanting answers to yes a very simple question that an apprentice electrican could answer. The question did not really have anything to do with thermal imaging that just simply was the tool being used to determine temp and it was apparent to me that Mark does not really understand how the camera detects temp he was capturing a temp of an electrical device that was shiney in nature with the E-value set on 95 thus when the actually the true temp would have been approximately 106 to 108 if taken in a conventional manner. I don’t understand why you would say that a level 1 2 or 3 might not be able two answer that question is beyond me. My point is one should know something about what one is taking images of, know what the standards are.

Yes David can be a little rough at times but if one has thick skin will probally survive to be the better HI for it. Why don’t we all just get along.

This is a very “Jerk” statement. Of course I promote proper training and the adherence to a set of standards. If I have time I will most certainly answer questions or try to be helpful. As a matter of fact, I spent a lot of time doing just that. There are many behind the scenes of the MB who have asked questions relating to Thermography. I certainly do not claim to know it all just because I have a Level III. There is a big difference in being helpful and talking down to someone. Mark simply asked a question! Regardless of weather or not you thought it was stupid or not, he didn’t deserve to be lectured by you.

Your over bloated ego has gotten the best of you. I don’t need to teach you a damn thing. By the way you talk here, you would probably just argue and claim you are always right.

Agreed. Inspectors should go get the standards relating to IR work. However, the later part of your statement is just more self-centered nonsense. Keep your own house in order and stopping spreading fear. Who are “those above us,” anyways?

Listen, I have always stressed the importance of getting the proper training for whatever it is your going to be doing. But, beating people into the ground here just for asking a question is not really productive. If you don’t have the time or don’t want to answer the question, then don’t post.

David, it seems to me that you are somehow taking his question personal. Mark’s lack of knowledge does not affect you one bit. Nor, does it reflect negatively upon you or the industry as a whole. To think otherwise is naive.

Kevin

You’ll be suprised to what other people know or don’t know!! Last I checked people get along by being nice and helpful to one another. Not just preaching or talking down to one another.

I wonder if Mark or any other Inspector will post an example or question here again? This section of the message board was developed for us to have discussions relating to Thermography and to share ideas and questions. I just think it is counter productive to just talk down to someone for just posting a simple question.

enough said…

Kevin

Kevin

Wow, what a pleasant discussion.

One cannot tell from the IR image whether the surface is shiny

or if it is a black plastic. Therefore, to assume that his emissivity

setting is improper is reaching just a little. To make that assumtion

we would need to see a digital image of same area. To many people who take IR training the most difficult area is in electrical componets and what is an abnormal temperature for a given usage. If you search the web and read different literature it is easy to become confused with what is correct and what is not.

Mark came to this board asking for some information. He was trashed.

A simple " Do some reading in your text books" along with " Nope, not a problem" would have been sufficient.

I also am an advocate for education. IR is a tool that can be very beneficial when applied properly. It also can take you places you don’t want to be. (court)

IMHO

Jeff

ITC/FLIR Level 1

IR for Weatherization

No Kevin surprised is one thing I am not as to what people know or don’t know generally speaking it becomes obvious very quickly. I was not trying to take sides both you and David should have taken that discussion to private E-mails Two wrongs doesn’t make a right

Nice post David , I do not have an IR Cam but I bite my tongue at “some” of the questions asked from lack of proper training.

In my opinion, if someone does not know exactly what they are doing with any aspect of the inspection business, they should be learning what they are weak in before accepting money for such an inspection.

Dale,

And you like David know it all? Some of the posts and arrogance on this MB absolutely floor me,

Chuck

Just for clarification:

I never wrote this up as a defect, I was just asking a question. When I took the infrared training, it was explained that many variables are involved when scanning electrical components including environmental temperatures, the load it is under, product material and location etc. I have not seen too many low voltage transformers run at this temperature. I know its not going to burn anything down…

I am a graduate of Carson Dunlop Home Inspection certificate and BCIT BC building code.

I have been in and out of the industry for years, my dad was a builder and my mom is a realtor.

David: I don’t really care if you think the question was stupid, it was a question on the correct board that myself and others could get something out of. Besides ranting and raving. I am glad you are a better inspector than me and thanks for clarifying that. Good thing your not in my area or we would really have some competition. Although, I am always up for a challenge

BTW: I charge more than $300

Mark:

Nice images! The thermal sensitivity of modern thermal imagers never ceases to amaze me.

Temperature limits for operating electrical components is covered in Infraspection Institute’s Standard for Infrared Inspection of Electrical Systems & Rotating Equipment.

Based upon IEEE and several other industry resources, this document provides temperature limits for items under full load as well as a correction formula for electrical components operating at less than 100% load. In order to apply values from the Standard, you will need to ensure that you have accurate temperatures for the subject component, ambient air temperature, and the amount of electrical load on the item of interest.

For more information or to obtain a copy of the Standard, please visit: https://secure.infraspection.com/comersus/store/comersus_viewItem.asp?idProduct=4099

From your imagery, it appears that the transformer is not connected to an electrical enclosure. This may represent an electrical code violation even if the transformer is running within its temperature limits.

Feel free to call me if you need further information.

You should see him in person, he’s no different.

I’m glad people are posting IR questions, it’s this interaction that helps everyone learn. If you think taking $10,000 worth of class training gives one the ability to know everything, your sadly mistaken. In most technical trades, it’s the hands on experience that helps. The interaction between fellow tradesmen is another huge factor in learning.

So please, please post questions and experiences. That’s how we ALL learn.

The day you quit learning, is the day your business fails.

This post has been very interesting to me. Last week the local Fluke Rep loaned me a TiR1 for 2 days to try. I’ve read up on thermal imaging, taken John McKennas class, was an HVAC factory rep, mechanical engineer, and do a lot of moisture analysis and stucco / EIFS inspections.

While using the Fluke around my house I noted several amazing things, When I pissed on the carpet in front of the toilet it made a really dark spot on the Fluke’s screen. When I was boiling eggs on the stove and shot an image of the pan and stove element - it showed up as almost white on the Fluke’s screen. Is this normal?

Do you think my emisitivity is set wrong? Is this an anomality because my pan was shiny? Is this telling me something useful?

My gut guess is - the dark spot was wet / the white spot was hot.

Am I ready to start charging others for my services?