Hello all this is my picture for the requirement of finishing the electrical course.

Where to begin with this photo. There is little room for expansion, and I would let the client know this. There are multiple double taps, Which are unacceptable. There are solid aluminum wires which should be evaluated by a qualified electrician. There is rust at the bottom of the service panel which may indicate moisture in the box and again should be evaluated by a qualified electrician.

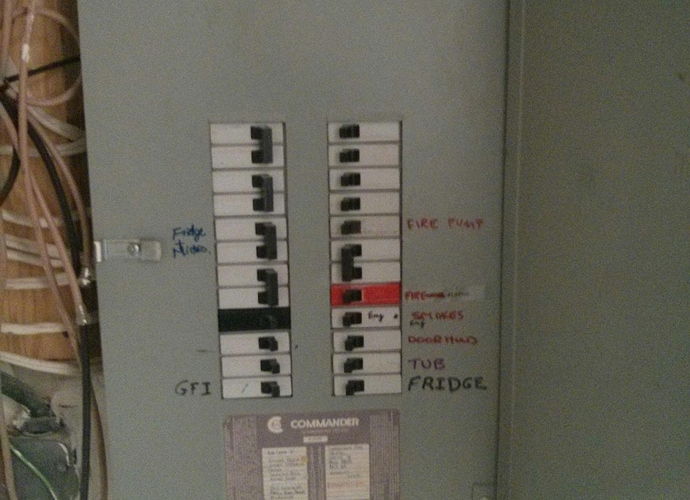

This breaker panel has a table indicating what each breaker services.

It also has handwritten notes beside some of the breakers.

Some of them don’t match so its true purpose is not known.

Breakers are to be clearly marked as to their purpose without contradicting notes.

Fire Extinguisher Maintenance and inspection:

Fire Extinguishers are an affordable necessity even in residential settings, as a minimum Extinguishers should be placed in areas of potential hazards such as Garage, kitchen and basement.

Fire extinguishers should be inspected monthly, be sure to give it a little shake to keep the powder from caking on the bottom.

db

GreenHouse inspections:

Greenhouses can be a great addition to a house to extend the growing season and and provide an outdoor activity when it may not be so pleasant outside.

As it is a high moisture area, inspectors should look for watertight fixtures and electrical services.

Excess moisture should be prevented from entering the house and should be exhausted to the outside instead.

db

The following was observed during inspection of breaker panel:

(1) During removal of dead front panel, one of six screws was defective. A sharp pointed sheet metal screw was used instead of the correct blunt ended screw.

(2) Debris in bottom of panel, wire ends and a screw.

(3) The master bedroom AFCI breaker did not trip when tested. Upon further inspection, the ungrounded conductor wire (black wire) was removed from defective AFCI breaker and double tapped into living room breaker above.

(4) Double tapped living room breaker.

(5) 240 volt breakers for the AC, Air handler and Dryer are utilizing white wire without markings (tape) to identify them as ungrounded conductor wires.

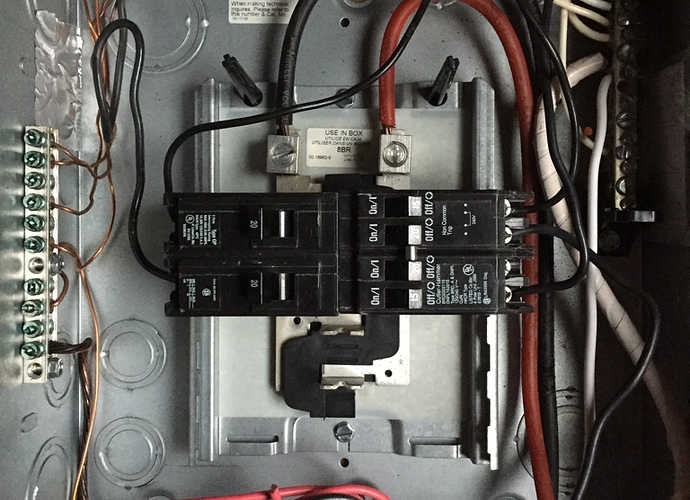

inspection of electrical service panel in the garage which is fed from a 50amp breaker on the main distribution panel in the house, this breaker was tested and when turned off it disconnects power to the garage. the garage is serviced by a cutler hammer panel rated at 125amps.

the dead front was removed to facilitate the visual inspection of the wiring in the distribution panel.

this panel is serviced by 2 phase 240volts with #6 copper wires, the black and red wires are hot and the blue wire has white electrical tape on it indicating it is the neutral. the blue wire is connected on the ground bus bar.

there is aluminum tape covering a missing plug on the left side of the panel. although it is covered, it isn’t using a proper plug cover and will be noted.

top left breaker, rated 20amps, feeding 12/2 copper wire to wall plugs

bottom left breaker, rated 20amps, feeding 12/2 copper wire to wall plugs

top right breaker, rated 15amps, feeding 14/2 copper wire runs the ceiling lights

note: right breakers at center are bridged and designed to run 240volt devices such as a heater. only one phase is being used at 20amp to the 10/3 copper wire coming from the bottom of the panel. the red wire has not been used and is not connected to the panel. this 20amp 120v circuit is being used on a single outlet for a 120v welder which is rated at 20amps.

bottom right breaker, rated 15amps, feeding 14/2 copper wire runs two ceiling outlets and the garage door opener.

note also: the incoming power wires have scratched casings from being pulled into the box. close visual inspection with a flashlight did not reveal deep cuts and are probably only cosmetic defects. to confirm this and the aluminum tape, an inspection by a qualified electrician would be advisable.

reading & writing assignment: I read the articles on ‘inspecting aluminum wiring’ and ‘electrical service from hell’

in the attached photo, this service panel has two defects to note. all wiring is copper, aluminum wiring concerns will not be an issue in this wiring scenario

-

on the left side of the panel is a missing knockout, this could allow moisture or other intrusions into the box

-

on the right breaker there is a double-tapped lug which is considered a defect. left uncorrected there is a potential risk of fire

a qualified electrician should correct these deficiencies

Have a question, In the basic terms portion it states the main panel is aslso known as service panel or distribution panel that has a disconnect. But on my quizz it states 'A.service panel that does not have a disconnect is a distribution panel.I beleive the quizz is wrong. Please let me know.

This electrical receptacle is on the back side of home. As a inspector this is beyond the scope to be tested and is considered very dangerous. This shall be reported on report and advise the client that this should be fixed immediately by a licensed electrical contractor. The wire branches to outlet is 14/2 AWG from junction box in attic, two other branches are 12/2 AWG, and the lead wire is also 12/2 AWG leading back to service panel where the circuit breaker is 20 amp. A 14/2 AWG is rated for 15 amp breaker not for 20 amp, this could be the possibility why this outlet caught on fire. There is no GFCI outlet or circuit breaker and box is not a proper insulated electrical box suited for outside elements.

Ladder Safety

Here are some Never’s Safety tips for inspectors and homeowners.

Never leave a raised ladder unattended.

Never place ladder in front of a door.

Never place ladder unstable or uneven.

Never use a ladder other than what it is intended.

Never tie or fasten ladders together to add length.

Never use ladder in windy conditions.

Never skip rungs up or down.

Never bounce on rungs.

Never sit on rungs.

Never over-reach on a ladder.

Never climb a ladder while holding tools.

Inspecting Residential Interior doors.

Home inspectors standards of practice indicates that little is required regarding the interior doors in a home.

The home inspector shall inspect a representative number of doors and windows by opening and closing them.

The home inspector shall report as in need of correction, cracks, brick cracks, out-of-square door frames, and un-level floors.

Inspection and Writing Assignment

How to Perform Residential Electrical Inspections.

During my inspection while checking outlets I noticed it appeared they had installed extra wide base trim and the cover plate no longer fit. It was removed and left off creating a fire hazard, and a potential shock hazard. Recommended qualified electrician move outlet, or to remove and or cut trim to size to allow proper outlet cover placement.

Reading and writing Assignment for How to Perform Residential Electrical Inspections

As part of the assignment I read two articles.

The first article was 10 tools every homeowner should own. It described the best tools for homeowners like number 1 being a plunger to unclog tolites and sinks. It talked about the basic tools and their uses for repairs in the home. Last of which dont forget the duct tape. Good article.

The second article I read was on Electrical Service Panels. It spoke of Safety with panels and described problems where inspectors have been injured/killed while inspecting panels. It gives good safety advice like checking the outside of the panel for wetness rust and moisture before even touching the cover. Good article.

This is an image of an older Square D 100 amp distribution panel that has been refurbished and repurposed to use indoors in a storage room.The panel has several reportable defects. The first being that as soon as you open the hinged door you notice that all twelve spaces were used at one time, whereas now, only four are used. There should be blank covers over the unused holes to prevent accidental shock or electrocution.The second is the dead front was installed using four socket head sheet metal screws. This is a major defect as the pointed tip of the screws could pierce the insulation of the ungrounded conductors causing an arching event or electrocution. Blunt tipped universal dead front cover screws should always be used. The third defect is that the manufactures label is missing from inside the cabinet. There are still several small certification labels attached, but the major label listing the panels capacity, approved aplications, approved breakers, ul listing, patent numbers and all the other really important stuff way to lengthy to list here. Recommended immediate replacement by a qualified professional electrician.

Main Service Panel

This is an image of a a square D panel with all square D breakers, except for #31. Upon inspection of the main service panel, my initial observations is that there is lawn equipment leaning against the service panel. The top of the service panel panel is missing the screws for the dead front on both the left and the right sides at top of dead front. The service panel is labeled well for all breakers; however, there is no main disconnect and is unable to be disconnected with 6 hand movements. After investigating, there is no other main disconnect upstream of the panel. I would recommend that a qualified electrician install a main service disconnect and at that time check #31 breaker to ensure that it is a correct square D breaker as there is no labeling on breaker. I would also recommend installation of the correct screws on dead front.

After writing my essay on using the XRF device to check for toxic drywall, it just peaked my interest on learning more about the drywall itself. While it seems the jury is still out on what actually causes the sulfur off gassing, there are several common factors that would lead inspectors to suspect that the structure contains toxic drywall. The first and easiest clue is that there is a strong sulfur odor indoors. The second clue is maybe to check out some of the metals inside the structure, for instance the appliances, drawer pulls, door hinges or see if you can find some bare copper to look at, like when your inspecting the electric panels or receptacles.The third would be if your inspecting in regions where it’s extremely hot and humid as this seems what may be the trigger for the off gassing. All the drywall tested that was manufactured in the US was clear of the defect. The only drywall tested that was defective came from China.

For this assignment, I have read the articles on abrasive blasting for mold remediation and AFCI testers. I have chosen to write on the article on AFCI testers.

An arc-fault circuit interrupter is required for all rooms in new homes after 2008-2009 depending on when the city ordinance decided to adopt the standard. The AFCI tester can be used to mimic an arch by creating wave form patterns similar to those produced by actual arc faults; however, their stand alone reliability is questionable. If used and the AFCI does not trip, the breaker should be checked to see if it functions as it should. The tester should be used as a first step in checking an AFCI breaker but not used solely to determine the AFCI breakers functionality, just as an added tool for inspector to determine if a closer look is required.

I just found the feel good article of the day, Doing Damage During an Inspection. I’ve been wondering if thats what the big insurance policy that inspectors have to carry was for, to fix the leg sized holes in the roof, the broken handles and latches on the doors and windows, and the screw driver holes in the rotten door and window trim. I would rather be the inspector known for finding defects and breaking stuff than the one that missed everything. 'Its not my baby ’ comes to mind and thanks for another concise article that comes with a happy ending.

The 200 amp Siemens panel was located in the garage. I removed the dead front cover and found no discrepancies. The copper branched wires and breakers were very clean with no signs of previous arching or over heating. The clean copper wiring also indicated even the though the house was built in 2004, hey day for Chinese drywall, this panel did not show any visual blackened discoloration of the copper wiring.

This is a picture of a distribution panel. The meter and main disconnect are located over 20’ away on an exterior wall. The service cable is sized correctly for the 200amp rating. All of the breakers are approved according to the panel label. All of the wire entrance connections to the panel are made correctly. The neutral bar and the ground bar are bonded together but since this is not the first means of disconnect they should not be. The ground bar should be bonded to the panel and the neutral should be isolated. Almost all of the neutral and grounds are double lugged together and should be separated onto their respective ground or neutral bar. There is too much space open between the bottom of the panel and the drywall. There are no open knock outs on the cover and all circuits are labeled.