I did an pre-sale inspection on a new build yesterday and noticed the electrician drilled 5 holes in multiple joists to string wiring. The holes are about 1’ in diameter and were made 2" on centers. The wiring runs 2"-3" above the bottom of the joists. They are in the first 1/3 of the beam. From my reading it sounds like the holes must be 2" apart. I recommended this be reviewed by an engineer. Am I off base on the distancing?

I doubt the holes were 1’ in diameter. Depending on the height of the joist, or the length a couple of 1 inch holes, spaced approximately 1/2 inch too close together isn’t going to be an issue for me.

Why don’t you post some pictures with some important information like the height of the joist, the span and the number of holes?

You do know that’s an engineered joist. What you referenced in your original post was for sawn lumber.

As mentioned, those are engineered I-joists and there are specific areas that can and can’t be modified, and from here, that modification looks to be wrong. I would recommend a Structural Engineer for further evaluation as well. It’s always better to be safe than sorry.

Maybe one of the SEs @rmayo that posts here will chime in.

Allowable Holes for Trus Joist Products - tj-9015 :: Weyerhaeuser

Also, in my area a fire wall is now required to be installed against the bottom of the joists or they should have a fire suppresion applied to them.

That coating/paint may or may not adequate.

I-Joist Fire Assemblies - APA – The Engineered Wood Association (apawood.org)

I appreciate the input. It looked wrong to me as well. I did recommend they have an engineer take a look.

If you can find the manufacturer of the engineered I joist, there is information that will help you in their installation instructions. This will save your client the cost of having a structural engineer look at the joist. It will also make you more competent in your inspections. Remember, your customer is paying you thinking you understand what you’re looking at.

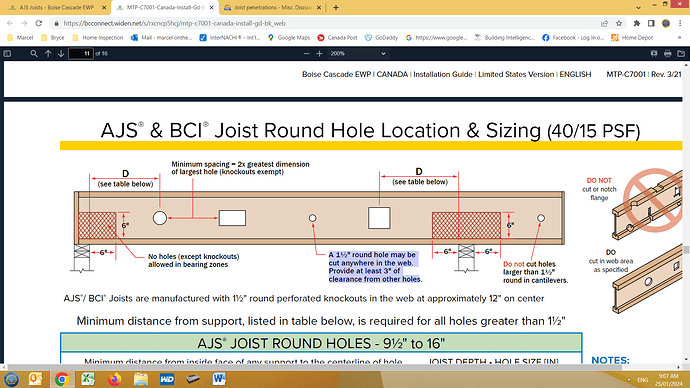

As Martin said, below copied from AJS Joists reads in part a 11/2 inch hole may be cut anywhere in the web. Provide at least 3 inch of clearance from other holes.

Good call.

Knock-outs installed at the factory in the I-joists is the preferred method of making holes in I-joists, any other type of modification should be closely scrutinized.

Another thing I see is the bottom flange appears to have a hole drilled into it. That would also need to be evaluated by a SE.

Do you guys often see white boxed new construction? I’ve only seen that once or twice when there had been significant water issues and staining during construction.

IMO not a drill hole. Likely a knot or other single layer/lamination hole in the LVL flange. Would not concern me.

Next time take down some information, brand/model of the I joist, span, depth, and spacing to double check against the manufacturer’s literature when you get home.

When a series of holes are bored very close in the web or does not meet the hole to hole separation requirements(such as distance = 2x diameter of largest hole), they can still work if you can cut a large round or square hole in the web that encompasses all of the close together smaller holes, AND this new large hole meets the required distance from end or intermediate bearing for the I joist

With this many holes, you would need a large square/rectangular hole. This is not likely to work when the holes are not centered in the joist span and being so close to the end bearing

Scott, small holes that close together are grouped together and analyzed as a rectangular cut out. I ran it through Boise Cascade’s software an it wasn’t an issue until you get within 3 feet of the end where the shear force in the web was reduced too much on a typically loaded I-Joist.

I really appreciate all the input and information! Thank you.

The construction in the area is complete. So, no labels and the beams were painted so I was unable to determine the manufacturer. The developer was not willing to disclose the name of the construction company so I was not able to contact them for more info.

The ‘hole’ in the flange is a knot in the wood.

From my research, and your input, I think this will be ok. I will still recommend they have a SE take a look. The Realtor thought that would be the best option as well.

Those holes appear to be very close to the bearing end. I am glad you recommended an SE.