I never see them in Colorado, so I’m not very familiar with them. With gas-fired combustion appliances, there’s the risk of explosion and fire from pre-ignition. What are the danger associated with oil-fired appliances like furnaces, boilers, and water heaters? Do they make oil-fired water heaters?

Excellent questions Kenton - I have to inspect my first one in the AM here in CO. Not sure what to look for other than have it insepcted by a qualified HVAC tech. Any help guys?

There’s a bit of info here that will get you started:

http://oee.nrcan.gc.ca/equipment/heating/13082

Carson and Dunlop’s report appendix has a bit on oil-fired heating equipment.

And, yes, there are oil-fired hot water heaters.

Kenton

Less danger the gas fired IMO

Problems Oil leaks

Things not to do

do not reset more the twice if flame is not present

Check for excessive soot. Keep in mind it will not be clean as a gas fired unit

Check flame

Check flue pipe

check limits / fan control

Check damper

Look for condensation if it is a high efficiency type going into old brick chimney

And one word do not stick your tongue on the electrodes lol

I didn’t even know anyone could buy heating oil here, Greg.

Wayne, what do you mean by “reset” and what is the danger if you do?

Kenton if you reset ( furnace didn’t fire) It pumps oil into the chamber . two many times floods the fire box and you will have a uncontrollable fire.

For fear of being shot down by the three stooges. The red button is a reset and should never be pressed more than twice. You will not need to touch this button in your inspection. You should also not view the flame unless you know what to look for.

Inspection of an oil-fired system is not anything like natural gas.

The lines are also different colors and must be installed according to proper guidelines. The guidelines are the CSA B 149-09

I would recommend you find the equivalent in USA.

Just a different name for diesel different grades

Kenton - I was surprised too - but Wayne called me and gave me some hints on what to look for - will try my best and will let you know how it went. I HATE first time stuff.

Trying to remember my CD course material, one thing I do remember is the reset button info that others have already informed you of. I will drag out the binder tomorrow at some point and see what, if anything I can add for you Kenton.

I have taken

Practical Guide to Safe Oil

Installation Codes for Furnaces and Boilers

Installation of Oil Burning Equipment

B149 Codes update

Safe Inspection of Oil tanks

Installed Oil tanks and furnaces

Monitors and wood stoves

Wett site basic

Natural Gas and Propane Installation code

Carson Dunlop heating one and two (Teacher)

HRAI Installation and designer

Advanced HVAC

And countless CE hours on HVAC

FINICKY F’D UP BOARD HERE!

By clicking on “go advanced”, just lost a post that took me 15 minutes on a long list of “things to check”

POS!!!

Hi Kevin I worked on Boilers, forced air furnaces, Licensed Oil burner Mechanic Unlimited BTU in Ontario for 23 years Certified underground storage. 15 years

Plus i have stayed in a Holiday Inn lolol

DANGER: Don’t listen to Linus and pee on the transformer ignition to test it (10,000 volts)!

There are about 46 parts in an oil burner gun, any one could cause failure.

The motor should run quietly and smoothly.

The squirrel cage blower assembly should not be rotted out. Must be cleaned periodically.

The oil pump should not leak.

Pop the transformer and examine the electrodes for arcing.

The nozzle should be clean and not drip oil. The nozzle should be changed yearly and must be the appropriate size. It must be the proper orifice size, spray angle and could be hollow or solid clone design.

The igniter probes discharge against the nozzle and must be properly adjusted (special tools required). The electrode gap should be no more than 1/8 of an inch apart and no more than one half of an inch above and forward of the nozzle. Porcelain insulators must be kept clean or they will short out. The spark should jump across at least a 1 inch gap with the blower turned off. Adjustment per equipment manufacturer.

The throat of the gun should be intact (not burned out). There should be no discoloration or build up.

The nozzle of the gun should not extend past the refractory insulation inside the furnace.

The cadmium cell above the burner must be clean and able to see the fire adequately.

The tank filter should be changed yearly.

Barometric damper operation should be free moving.

Check for delayed ignition at start up. Should fire right off and not pop or blowback during ignition.

Pulsation noted during operation is caused by positive pressure in the combustion chamber indicating there’s not enough draft.

The draft should be .02 inches of water gate.

Positive pressure may be caused by having the air shutter open too much, the chimney is too small or partially blocked or not high enough.

If anyone made any changes to where the tank is located, the type of pump may not be compatible if it is a single stage operating in vacuums at or above 15 inches of mercury. This causes the oil to foam before it reaches the nozzle to be atomized.

A faulty nozzle has an irregular flame pattern. The flame tips should be sharp (but not excessively).

If you see oil on the floor of the furnace room it is a serious condition. An air leak in the oil suction line causes the nozzle to drip. It can be from loose connections or fittings or from a bad pump seal.

Unusual sounds during operation indicate worn and broken parts which should be immediately replaced as failure may cause a significant breakdown which could be avoided.

Noises come from loose fans, loose shutter, worn pumps, dirty strainer, air in the oil, motor coupling is worn, motor and pump are not properly aligned, relay contacts not seating, restricted oil lines,

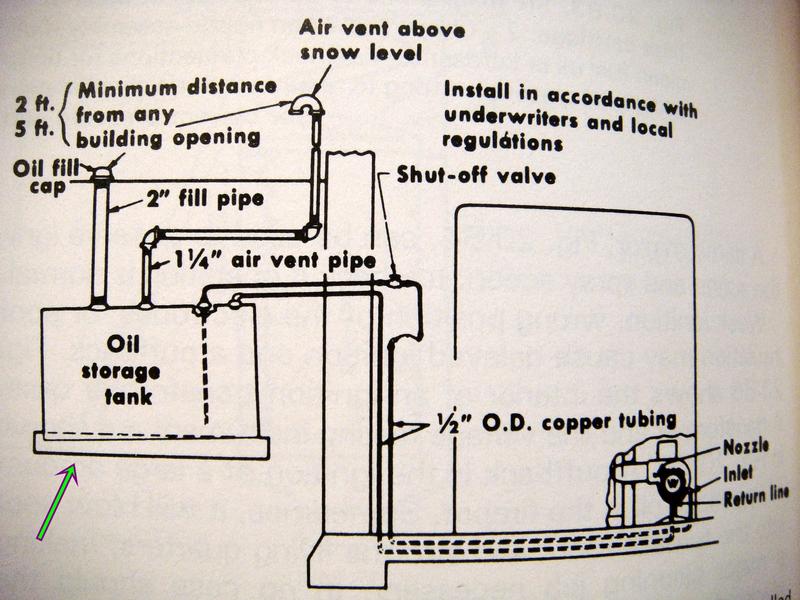

Any indoor tank should be at least 7 feet away from the furnace.

The oil storage tank should be tilted away from the outlet pipe to collect moisture and crap.

Any black soot observed in the furnace room is an indication of blowback and improper ignition current or in the past.

I taught air conditioning installation to the oil burner technicians at the American Fuel Institute. This is what they taught me!

Too bad we lost you to USA. Oh yah I stayed at Holiday Inn too.

I have not installed for about 7 years and still scratch my head every time I see a wrong installation here.

So to make this brief and to the point start reading everything you can find on installation and inspection of Oil fired boilers, Water tanks and furnaces.

The oil storage tank should be tilted away from the outlet pipe to collect moisture and crap.

Is this an error or is it different in the US?

Here we are to tilt it towards the outlet.

If the filter is outside and temperatures are low enough fuel oil will gel.

David you for forgot type w (Semi hollow) we used to call it now it is all purpose . lolol

Now do not yell at me .

gal per hour is based of psi of the pump older burners lower pressure 105 to 110 PSI

Some ares require a spill container under the tank if inside

No more than 500 gal of storage inside ( use to be in Canada)

If the tank is above the burner a safety valve should be installed with a fuse-able link in case of fire

Trying to kick out the cob web’s it has been a while

It is Canadian spelling keep up will you , I understood it lol.