Hi this is Carl Embertson and i recently retook the Online Inspector Examination and discoered theat I need to take this HVAC course and Its only a matter of time and study then I will be better equipped to pass the main exam!

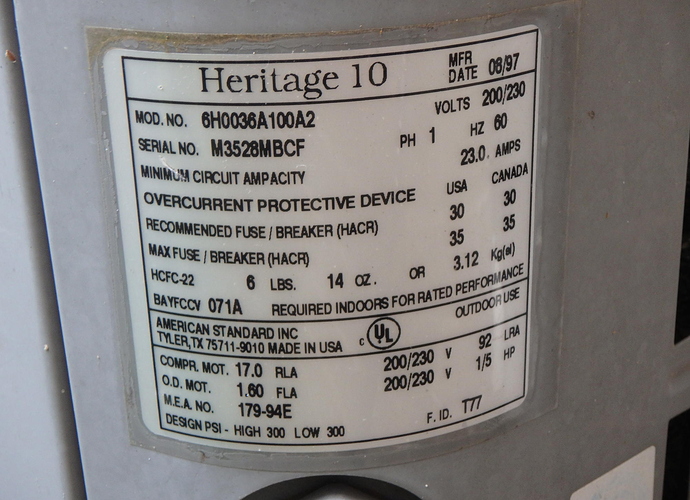

This is a split system unit. It is a 1997 unit. This unit is currently 19 years old and may be approaching the end of its useful service life. Recommend having the unit serviced by a licensed HVAC tech to prolong its service life. Budget for an eventual age related replacement.

Recommend having the coils cleaned and all vegetation and debris removed from around the exterior of the unit for proper airflow.

Hello, my name is Chad Maddox. I will be writing my essay for this class on the article “Crawlspace Hazards and Inspection”, since many components of the HVAC systems in my area are located in the crawl space.

First and foremost is safety. When inspecting a crawl space I am always equipped with coveralls, gloves, knee and elbow pads, and my respirator. Tools I generally carry with me are flashlights (2), moisture meter, camera, and circuit tester for identifying live wires. I also always take my cell phone if I am on a property alone, just in case I were to get stuck or have some other emergency issue.

When inspecting HVAC system components in a crawl space, I check for proper installation of duct work, proper ventilation of the crawl space, and if the air handler / furnace is located in the crawl space it is checked at this time as well for proper installation and condition.

At this home I found this condition on the Lines coming out of the home to the compressor unit. As you can see the insulation on the refrigerant line is starting to deteriorate from weather and UV exposure. Also the relay control wires are spliced improperly and should be inside conduit for protection from UV, weather and mechanical damage. By code all wires should be protected on the exterior of the home.

“Evaporative Coolers” is the article I chose to read.

I have an Aunt who lives in New Mexico and as a kid was the first time I saw a swamp cooler. I was amazed at how cold the house became at night. The cooling effects of a swamp cooler are unfortunately only useful in dry climates as the water must be able to evaporate. With the average humidity on the Texas Gulf Coast being about 75-90% year round they are not effective here. If one was used here all you would end up with is a hot muggy home full of mold.

This is a Carrier Evaporator (or Heat Pump) Label.

It states the Date of Manufacture as February of 2006.

The Serial No. will indicate 0706 which should be the 7th week of year 06.

It also indicates that the Refrigerant gas for this unit should be Freon R-22.

Indoor Air Quality

The term addresses the air quality inside and around building structures, especially as it relates to the health and comfort of the occupants. Air quality can be affected by gases like carbon monoxide and radon, particulates, microbes as mold, or any element that can induce adverse health conditions. Controlling the source, the use of filtration and ventilation that dilute contaminants are a primary methods for improving indoor air quality in most buildings. Residential units can further improve indoor air quality by routine deep cleaning of carpets and area rugs.

Here we see an oil storage tank, shut off, filter and supply line. The oil supply is located in a basement that has some moisture issues, hence the light surface rust on the tank. Other than the light rust, everything appears to be in good working order and correctly installed. The one thing I would note is that it appears the oil filter has not been changed in quite some time. This could be a sign that the furnace has not received professional care in the same amount of time, as filter replacement would be part of a routine tune up.

I read Pellet Stoves For Inspectors to add to the heating portion of this section. Pellet stoves are very common here in NH and are used as supplemental heat in many homes. I was surprised to learn that some models of pellet stoves require as little as one inch of air space to the wall behind the unit. The fact that they are designed to keep the majority of their heat near the front, allows them to fit in tighter spaces. The fact that they use smaller (3") exhaust vents also allows easier placement of the units.

For this class I read an essay on The Duty to Warn: A Home Seller’s Guide to Immediate Hazards.

Not everything is written in stone, but this article helps draw the line between confidentiality and public safety. Not only do we have to weigh the rights of the client against the greater good of protected them from harm, we may also find ourselves in a situation where a serious injury or death occurs because we didn’t resist the urge to please all parties and state firmly that this is more than a defect, this is dangerous. I will be working in California and will inquire with the realtors board for clarification of “reasonable duty of care”.

My weakest area of my inspections, a much needed course to reeducated myself.

Great course, lots of great technical information. The picture that is attached is of the suction line of an air conditioning system. As you can see, the suction line is missing a portion of the insulating material, which causes a loss of efficiency in the system.

The article I read was on central air conditioning system inspections. It’s important to inspect your AC system to ensure it’s properly maintained and functioning correctly. One should inspect the exterior condensing unit, paying close attention to ensure the fins are not bent/damaged. Inspect the condensate line to ensure it is draining properly. Inspect the filter media and clean or replace as necessary.

I inspected the the whole unit including the outdoor condenser and the central unit in the attic. In the picture you will see the outdoor condenser that push the condensing liquid to the central unit. Located in sight of the unit is a shut off switch. All parts of the fan looked to be operating correctly.

for this part of the course i chose to read central air conditioning system inspection.

what is nice about this article is that it gives you information to forward to your clients. what a better way to convey your professional acumen then not only providing a top notch inspection but then throw in some valuable information regarding how to keep their air conditioning system running for years!

cleaning the condenser unit and components. remove any debris and trim any foliage around the unit to ensure proper air flow. make sure to oil the fan motor!

check the condensate line for leaks and obstructions.

clean or change your air filter. cant stress this point enough. explain if necessary that if the dirt isn’t on the filter then it’s on the evaporator coil!

finally, remind them to get their system serviced regularly by a licensed technician.

during the course of an inspection, i discovered the condensate line to have tape to hold the connection together. quite odd since all the other joints are glued.

this union needs to be watertight to avoid damage from condensate discharge. this type of repair is a simple one. i would recommend that the client either repairs this connection themselves or by a qualified technician.

i would also add that the client does not necessarily need a air conditioning or plumbing company to correct this issue. a good handyman can perform this service for a much lower cost in most instances.

Writing Assignment:

This data plate for an exterior condenser unit of a central HVAC split system was barely readable, yet good enough after the contrast was tweaked, to identify and confirm some interesting, but not required by the Standards, information. The first line is the serial number. Using the Building Intelligence Center website, I was able to identify this Carrier unit as having been manufactured in the 39th week of 2005. The third line down is the model number and the center series of numbers, after the letters, tells us that the “48” represents a 4 ton unit (12,000 BTU per ton). Finally, further down on the “compressor” line we see that the RLA (rate load amps) is 20.5. Since this unit was manufactured in 2005, dividing the RLA by ~5 (5.125 exactly in this case) confirms for us that this is a 4 ton unit. In addition, no presence of a heat pump reversal valve, along with a gas meter on site, confirmed that this unit is attached to a gas furnace before even getting inside.

Research Assignment: Electronic Signatures for Home Inspection Agreements.

There are differences between digital and electronic signatures. The digital discussion is beyond the scope of this assignment and the “electronic” is applicable to most inspectors. The article argues that contemporary standards and current law are fairly protective of authorizations received from clients via electronic means for their pre-inspection agreements. Not including the interstate federal statutes (e.g. ESIGN), since most inspectors are dealing with intrastate agreements, there is the Uniform Electronic Transactions Act (UETA) which 47 states have adopted. There is the option to insert specific legal language into your agreements. There is also the doctrine of promissory estoppel, the concept of unjust enrichment, and the partial performance exception. All of these standards make electronic signatories fairly robust when it comes to binding contracts.

Ready to start HVAC course.

furnace pic.pdf (96.6 KB)

This image shows wiring attached to an oil burning furnace that is not contained inside a junction box.