Thanks for posting this mess Nick, I built around 50 defects into the panel and although it may be difficult to tell which ones they are, the time when we can look at it in person will be the best way for me to describe what I did to this nice new equipment!

JoE;

It might take some time to wright up all the defects, But it is a good learning curve.

Keep up the good work.

Was nice seeing you again at the convention, Glad they gave you a repreeve

Regards Len

Joe, is this the same panel you shipped to me?

Yes it is Nick, and Thanks Len, I am happy to be back!

If any NYS Full HI Provider needs an Instructor I am recognized as a NYS Technical Instructor and can lend a hand and present a 6 hour electrical seminar, maybe I can come to LI again, my old home town was Corona, NY.

Hey Guys,

I most certainly think every HI here should get a pad out, get a nice sharp pencil and look at each image one at a time.

Not every defect will be seen as images do not always tell the whole story but I challenge you all to write a list of defects from image to image and POST them here.

Nice work JOE.......some are obvious and some are not so obvious...thats the best way to train.....

I will most certainly start my list.....always easier when you are making the defect than trying to notice them.......nice learning experience for members.USe the following format…

IMAGE # 1- Defects

A.)

B.)

C.)

and so on…

P.S. I would say # 14 is my favorite image…

ACTUALLY…would it be considered for some CE points IF you did the list and sent it to ME and JOE to review them versus posting here…what do you say NICK…

Joe you are right, you have to see most of these types of electrical problems in person, pictures just don’t have all the right angles and distances. It would take awhile to study the panel in order to locate that many defects.

Looks like that panel would be referred to a licensed electrician by any home inspector even with just a quick glance. Many inspectors do not believe in listing every defect when a certain number per system has been found, they just refer the whole system to the tradesman. There are pros and cons to this method. I have found that contractors usually only repair the exact problems listed in a report and do not go any further. Usually they even leave out a few in the report and add a new one or two.

The one I built is a tricky one for the most part, many of the problems would be missed by a lot of inspectors and a few would be missed by every inspector including myself.

The reason that I made mine somewhat tricky is because everyone that examines it already has the advantage of knowing it has been preloaded with problems.

Actually I think it is just good practice to try…most certainly you will stop at some point and simply refer it on but I think it is nice to play with for new inspectors and even some seasoned ones to SEE if they can find the defects…

Sure we wont see them all…but many are obvious and those are the important ones…when someone starts missing the obvious is when we start to worry…lol…

I must say however Joe…could you not find any RUST to smear on it to make it look more realistic …thehehehe…we need some nasty, rusty, cobweb filled ones also…lol…Where Jeff Pope when you need him…lol

Thanks Bruce.

Paul: Rusty buckets are easy to find and list, and the panel I built was on the spur of the moment during the two days my wife threw me out because she was the contractor for the kitchen and bathroom remodel. Why after traveling overnight now still on the Amtrak to be into Boston after 24 hours, I was told to get out in the morning so the painters could finish their work!

As long as the Lady is happy that’s what counts and she surprised me saying we would go to Italy again this Summer.

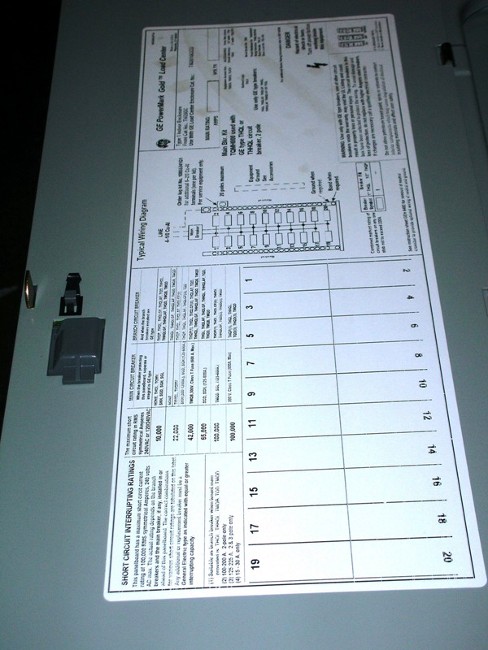

OK, first the directory is not complete. We should be sure that it is accurate and specific, if not call it out as a defect. The other information on this glued page is also very important, and it would be my first discussion and here we will find the instructions, one of which said only use my breakers Dude!

**

**

#13.

Give me more!

Will do Nick, can you take some real close ups of the page above, this way we can discuss the instructions, not saying that the HI should list all only to have them be aware!

#15

The two lower GFCI CB’s and the two AFCI’s on the right are not of the same manufacturer and the use of the wire handle tie does what?

It does nothing it was just put there to make it clear that the use of anything other that an “identified” handle tie is not permitted.

Kind of like shooting fish in a barrell. I’ll start w/ #1.

- Bare (#6 or#8?) too long, not installed in a workmanlike manner. Too close to energized parts.

- Black conductor not identified as a grounded conductor (can be id’d w/ white tape if #6 or larger). Can’t tell what size it is from pic.

- Same as above connected to ground or neutral lug (can’t tell from pic#1) on the right side of the pic.

- 100 amp providing overcurrent protection for what looks like #6 or #8 (can’t tell from pic) copper wire.

"OK, first the directory is not complete. We should be sure that it is accurate and specific, if not call it out as a defect."

Joe, this is something I have wondered about. Just how specific do you want to make a panelboard legend? I agree the dedicated circuits should be properly identified, but as far as general lighting I think it is better to be general. It would be impossible to list every item on each breaker and I feel that using descriptions like “East bedroom south wall” etc. is creating something that someone like a homeowner could count on for being accurate and possible be hurt or killed as a result.

**Also liability wise, I feel it is wiser to label all the general lighting circuits as “General lighting and receptacles” without going into detail. I always inform homeowners that a panel legend is only a guideline and should never be taken as gospel. **

Not to mention the tie is between a GFCI and a Standard Breaker…can you say NO…NO…Big Time…:)…and as JOE said…the tie is can you say…WRONG…at so many levels…lol

OK…How many of you see a broken breaker handle and say…aww…poor handle…thehehe…actually it is a true defect and should be called out…oh of course the handle tie…the nice pretty white one is WRONG…now I can’t say right off if the Sq D breakers should be in this panel…lol…Some are SWINGERS now days…thehehe…we all know what that means…RIGHT NICK…just kidding…aw man I will pay for that joke…

actually I believe I count (3) different models in that panel…lol…did they actually FIT or did you break out the dremel took Joe…

Instead of just listing “receptacles” and “lighting” or “motor”, best to say “Bedroom Receptacles” and “Kitchen Lighting”, etc., and “AC Unit.”

I often wonder what the directory should say in an area where English is not spoken? I passed through a Korean area last year and looked at a panel in a restaurant and was unable to read the ???

What does a HI do when this arises?

James:

The EGC terminal bar is not where it is supposed to be, and your comments cover some of the defects. I will have to see that panel again and list the errors, I was having so much fun I just kept beating up on that cabinet.

Paul:

Yes, three types of breakers and the SQ D doesn’t belong in this panel.

I hope that the “3 pole” tie doesn’t confuse anyone – it is not a 3 phase supply, the panel is for a 3 wire 120/240 volt system.