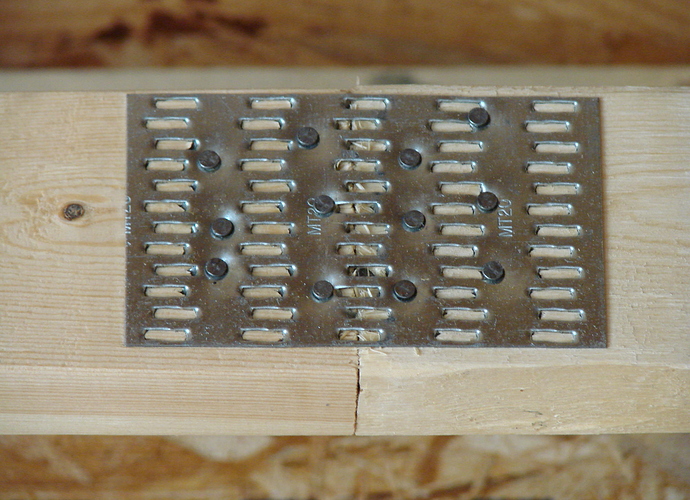

What would you write about this? Found on one truss.

Looks like someone just did not trust the truss plate connection and tried out his joist hanger nail gun. LOL

I wouldn’t write up anything. Looks like the wood hasn’t split. Providing stub nails were used and they weren’t protruding from behind, I’d say it’s acceptable.

Mending plate, field installed. What was that for? Looks like white spruce, which is not normally used in a truss assembly.

Sorry Brad, I don’t remember what inspection this was from or even if it was from an inspection. For a project, I’m going through a lot of photos of defects from a big library of photos I’ve collected over the last 8 years. Most are mine, but many are not from inspections. I can’t tell you anything specific about this photo.

Looks like doug fir and typical rolled-in-place gangnail to me to me. Sometimes you see nailed gangnails after they have been pried off and then replaced, but then you can usually see damage to the gangnail like pry marks or kinking where the plate was bent. I don’t see any evidence of a problem but am suspicious because I don’t see any reason for the nails. They wouldn’t be necessary under normal conditions.

What would you write about this?

Ask EVERY firefighter which they would like: one with nails or one without.

I overnailed each of mine during our barn build. Much safer and less chance of collapse during a fire.

Really? Firefighters have an opinion about gangnail connections? I’m in Mexico. Firefighters here (the few there are, all buildings here are made of masonry) never heard of gangnails. Stephen, you really think many firefighters have an opinion about this? I could email the fire department back in Boulder. It does make sense.

So I guess that means the way trusses fail first in a fire is at the gangnails, since wood often outperforms steel in a fire. True?

Would you rather trust a metal fin that is 1/4 inch deep or nails that are an inch deep? Inspecting a truss that has been fire damaged, besides full failure, the char is usually a 1/4 to 1/3 inch deep. The same depth of the gangnail plates.

For more information here is an interesting read in pdf format.

I agree, in a fire, I’d rather the better connection. But these trusses weren’t fire damaged, so what would you write Stephen? That’s the post question.

I wouldn’t write anything. There is no issue.

no issue. This used to be part of the manufacturing process. Tack the plates with nails and flip trusses and then send through the roller press.

Nails are the problem.

Agreed. For whatever reason those nails were installed, I see no reason to be concerned.

It is in no way any different than some truss hanger installation requirements faced with at times, where the hanger nails go through the truss connector plates, depending on the installation type.

Given that there is no real context here I wouldn’t offer anyway of writing something up.

To me it’s all about the context, which we don’t have in this case.

If I found it on an inspection I’d be looking to see if other splices were treated the same or not.

Typically they used T-nailers to tack the gangnails in place before pressing them. It looks to me like this was nailed after the gangnail was pressed or there would be split wood visible where the nails are close to the break.

I wouldn’t write anything about this either, but I’d be looking at the rest of the gangnails more closely than usual.

See anything else wrong in this photo?

roofing nails and nail gun nails in the truss plate. Wrong kind of hanger too!!

Bingo, bingo, bingo! Although I don’t think twice about those little T-nails.

What do I win, never won at Bingo. LOL

I agree, they don’t amount to didiley.