To fulfill requirement of taking an image and of a system / component that was covered in the course of How to Inspect HVAC Systems, I chose this image of a condenser unit to an AC system. Two things were written in the inspection report about this unit. (1) some of the fins were bent; recommended having them straightened back (2) the sheathing and insulation to the freon gas tubing was torn; recommended repair. The AC itself was operating within normal limits with a difference of intake / output register air temperature of around 18 degrees.

I read a couple articles: (1) Clothes Closet Lighting and (2) CLUE Reports.

I definitely learned more about what I need to be looking for on my inspections of closets (with or without clothing!). I have a much clearer set of guidelines to go by on clearances for the various types of lighting.

I really didn’t have a clue what a CLUE report was till I read this article! I’m going to request the seller / Realtor show me a CLUE report before beginning any inspection so as to help me focus on certain areas mentioned in the report. I’m also going to advise any seller that is having a pre-listing inspection to also get a CLUE report as added protection from lawsuits.

Anti scald valves mix cold water with hot water so that the hot water that leaves the valve is not hot enough to scald the person. Scalds account for 20% of all burns . More than 2000 American children are scalded each year. Scalding can be an expensive hospital stay and may require surgery. Scalding may lead to other injury like falls and heart attack. Water 160 degrees F. can scald in 0.5 seconds

This home has 2 units.

The main system is for the downstairs living area and is a Rheem 4 ton heat pump manufactured in April 2001. The disconnect is located within three feet of the unit.

The A/C unit is functioning correctly within its operating conditions at this time.

The heating unit was not operated per ambient outside temperature.

This unit has not been serviced recently and would recommend it be serviced by a qualified HVAC technician.

Inspecting Heating and Air condition systems: This is probably one on the most detailed parts of an inspector’s knowledge base. The inspector has to write a short concise description of the heating system that the consumer can understand. The inspector must take care to explain that the system was checked under normal operating conditions. However the inspector should be able to answer basic questions about the operation of the system.

Reading and writing assignment,

Inspecting the central air conditioning system: First of all, the system should be inspected and serviced annually by a qualified HVAC service technician. However, there are some things the homeowner can do to help insure the system operates at its best. Proper maintenance is essential for the systems efficiency and life expectancy. Things like, changing the air filter regularly, keeping the outdoor condenser coils and indoor evaporator coils clean and making sure the condensate drain is clear, are all things a homeowner can do without any special training.

This is a picture of a 3.5 ton heat pump (inside condenser/air handling side). The required in sight cutoff is obvious as a fuse panel is present behind a accessible cover. This unit services a home that is apprx 2360 sqft and is within the rule of thumb formula discussed in the text for sizing (3Tonx700 = 2100 plus the .5 equals 350 sqft more in total up to 2450. It is a 2004 year model and a 12 SEER.

Central Air Conditioning Unit

This is an image of the A/C Unit located at the side of my home. The second image is a shot of the data plate. To determine the size of this condensing unit, you refer to the model # on the data plate.

The model # is SCU10G36A – 1. The size of this unit is a product of the # of BTU’s divided by 12; in this

case: 36/12 = 3 Ton. The second piece of information from the data plate is the serial # 1604L02661.

If you go to: www.buildingcentre.org you can check the manufacturer and find the date that that piece of equipment was manufactured. In this case, it’s an Armstrong product, which when completing the search on the website, shows the types of serial # indicating that this unit was manufactured in 2004.

I had a HVAC condensation backup problem years ago that resulted in water leakage in the house. I discovered a clogged condensation line and corrected the clog by using a shop-vac in blow mode and directing the forced air thru the condensate line. That cleared all the debris and backed up water. I periodically pour a small amount of bleach down the condensate service line to remedy a future problem. Also I often check for water properly draining while the unit is in the cooling mode.

There are several methods of heating the interior space of a residential property. In my area, the most common is forced air mid to high efficiency natural gas units with an central A/C unit which sits outside (split system).

The other system that has gained some ground in popularity is the geo-thermal option. These systems are very effiecient, cost effective in it’s operation but prohibitive in nature when it comes to implementation. As the size of the property would be considered within the design criteria, the application on a horizontal v/s verticle system would need to be determined. The costs associated with a horizontal system would be less that a verticle system, providing you have the land available. In most cases, the land is not available and therefore a verticle system is used. The cost of this is considerably higher due to associated costs of excavation, drilling, etc. Therefore, when weighing the inplimentation costs associated with geo-thermal systems, one has to consider the perceived savings over a longer period of time to understand the benefits of this system. As a conventional natural force air split system would cost approx. $11-14,000 to install,with a life cycle of 25-30 years.A geo-thermal system may cost as much as $60-70,000, with a life cycle of 50-60 years.

This is a picture of a pan under an evaporator coil in an Attic on a heat pump. It is filled with water and is draining through the overflow line to the exterior of the house. The condensate line is not clogged up as far as I can see but apparently it is not working properly. I would recommend a licensed hvac technician further evaluate the unit.

this is a picture of a heat pump in a attic space it has the required clearance

- bathroom ventilation

In my area, bathroom vents seem to be one if the most improperly installed system. Very rarely do I see one that terminates to the exterior, most vent to the attic or right under the sheathing.

The article explains that all bathrooms should have a ventilator regauardless if they have a window or not. Mainly because no one is going to open a window in the winter time.

Mold can be a major concern with improperly vented ventilators and an inspector should always remember to check to see if bathrooms are vented properly.

- Inspecting ceramic and stone tile

Ceramic tile can be inspected for unevenness, cracks, crazing, and grout not being not sealed. Uneven tile can be trip hazard. Cracking tile can be a symptom of house movement or just improper installation. Grout should sealed periodically.

Also, stone is pourous and should be sealed fairly frequently to pretect it.

The image depicts the interior view of the inner evaporator coil of a fully depreciated heat pump system. The coil has significant surface corrosion as well as a great deal of debris that has passed beyond the filter and adhered to the inner coils thus blocking the direct contact of airflow through the coil. This system is no longer cooling efficiently.

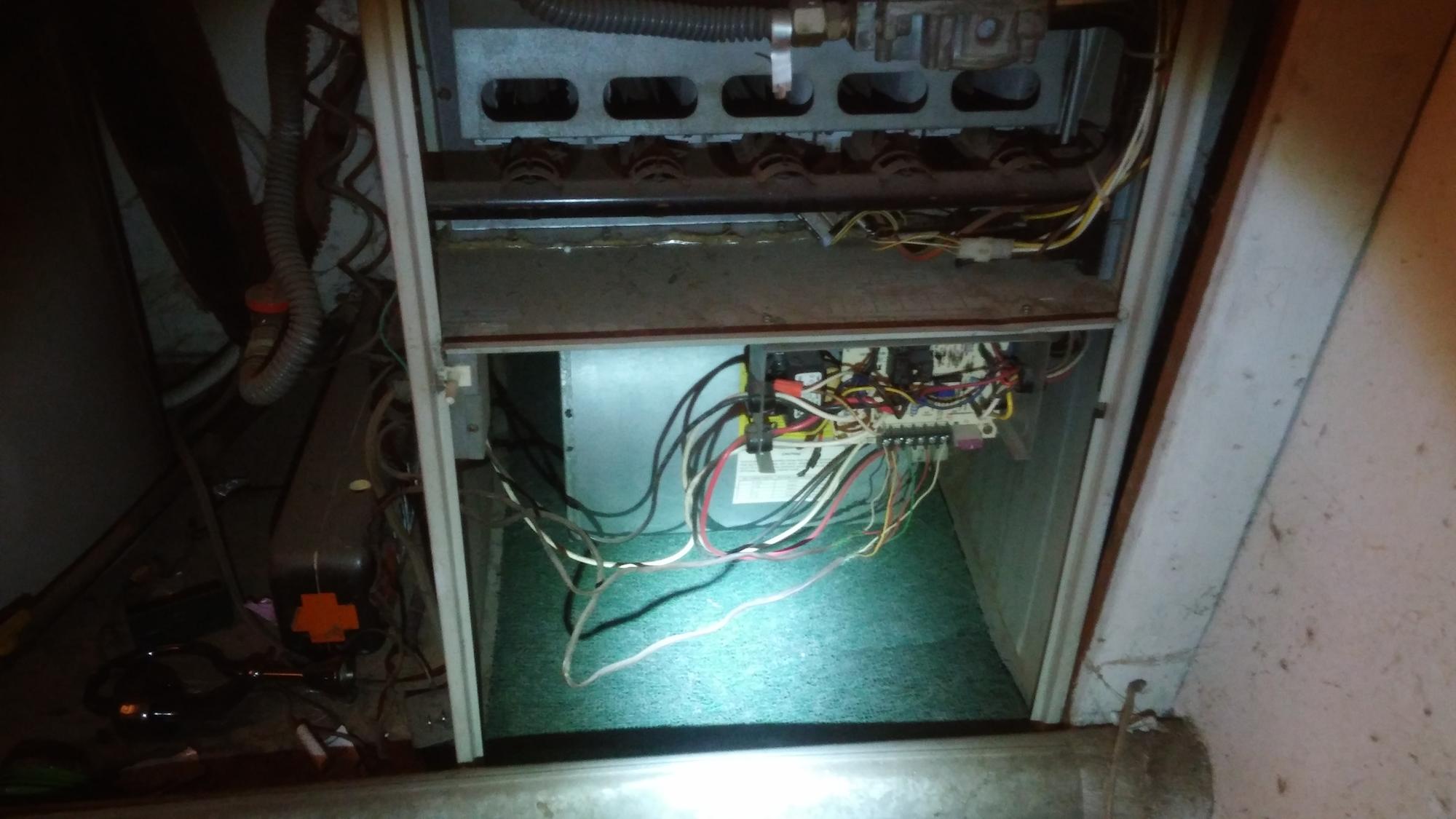

I inspected the furnace in a friends home, during my inspection I found that this unit was built in June 1988. this is a up flow natural draft furnace. in the picture you will notice that this unit has a washable filter that seems it has not been washed in a while as well as it is missing the top retainer spring, they have also used the area directly to the left of the furnace as storage.

in this assignment I read an article on heating ventilation and air conditioning. the reason I read this article is because this is the module I am currently working on and I have found this unit very interesting. in this article I read that not cleaning the filter is not only bad for your pocket but its also bad for your health. see if the filter is dirty its going to strain the motor therefore the efficiency is going to go down therefore it is going to reflect in your electric. the reason its bad for your health is because you are allowing or forcing I should say dust and particles that can agitate individuals with asthma as similar breathing issues.

I have pictured here an outside unit (Condenser). Its age is not yet found. The aluminum fins are oxidized and eroded off in some areas. The fan is running and the unit is working properly. The paint is faded and rust is popping up on the exterior case. A disconnect box can be observed in the picture. This is a switch that cuts the power off to the unit in case servicing is necessary. The outside unit also houses the Compressor for the unit. The compressor compresses refrigerant gas back into a liquid which is sent to the capillary tube just before the Evaporator coil to become a gas again in the refrigeration cycle.

Asbestos is a mineral fiber that can only be identified by a special type of microscope. There are many types of Asbestos fibers. Breathing these fibers can cause a form of lung cancer, over time. Mesothelioma can take twenty to thirty years to develop after exposure. Asbestos can be found in floor tiles, insulations, cement roofing, products that insulate from heat. You can not tell if a material has Asbestos in it simply by looking a sample must be analyzed by a qualified professional. Taking samples involves being alone in the room when sampling, wear disposable gloves, do not disturb the material any more than needed. Send the sample to an accredited National Voluntary Laboratory Accreditation Program (NVLAP) Your State or local Department may also be able to help.

I chose the article on back drafting.

Back drafting is a condition that is caused by exhausting indoor air with exhaust fans, fireplaces, dryers and improperly configured flues and blockages. Combustion gasses are pulled back into the home through draft diverters due to low indoor air pressure.

Back drafting should be tested during the inspection by means of a CO meter or smoke simulator held at the draft diverters while running all possible sources of exhaust in the home.

If back drafting is detected, then additional outdoor air will need to be installed near the gas burning appliances.

One of the useful tips in this coarse was how to determine the age of an HVAC system. In the attached image you can see the manufacture date in the upper right hand corner but I assume this rarely the case. After going to building center.org you just find the style of unit by using the serial number. My unit was style #3. After that you scroll to your style number and it shows you the year and week of the date the unit was made. Although not a requirement of home inspectors, , I can see this being very useful information for someone buying a home.