Hello students, I am completing the writing portion of the HVAC course. The article I’m writing about covered pilot lights. To sum it up pilot lights are out dated and relatively dangerous. Photo resitors(read the light of the flame) thermometer(reads the heat of the flame) or a voltmeter are better alternatives. If possible the home owner should replace an old pilot furnace with one of these other options. Annually many homes are destroyed by blown out pilots as well as the fuel loss and pollution.

Inspection for a 80000 btu furnace & A/c first thing is its out of 1yr. warranty I can se it has water collector replaced, has been well maintained very clean,needs filiter change. the only recommendation would be to add a humidifier

I inspected an up flow natural gas furnace. This furnace was made in 1975 but appears to be in working order. It has a constant pilot ignition. The burners lit and the blower started a few seconds after when thermostat was turned up. Sticker on the side indicate the last cleaning was done in 2002. Recommend cleaning the furnace and changing the filter. Given the age of the furnace, it’s recommended to speak with a licensed mechanical contractor about servicing or replacing with high efficiency furnace.

This picture represents the evaporator coils of a gas exchanged air-conditioning system. The aluminum fins look good without any damage. There does appear to be some dirt on the surface that may benefit from being cleaned by a service technician.

Evaporative Coolers

Pulling hot air over evaporative pads can reduce the air temperature 15-40 degrees. Although they work well in dryer climates, they may not be as beneficial in climates with higher humidity. Evaporative coolers are efficient and can do a great job at cooling the indoor air.

Home heating oil tanks

When inspecting oil tanks look for leaks, rust, or damage to the integrity of the tank is intuitive. It’s also helpful to know about the support system supporting the tank. Considering the load, inspectors should pay close attention to the stability of the tank. Finally, it was very useful to learn about oil spills and how to handle them.

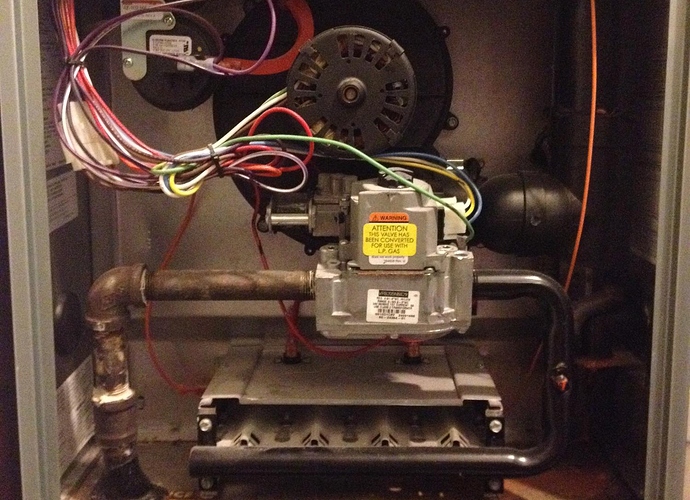

This is looking inside the panel of a propane-fired, forced warm-air heating system. This particular system is downflow, which means the return air comes in through the top of the furnace and flows to the bottom where it is supplied to the house through ducts and registers in the floor.

In this picture we can see the shutoff valve (red knob), the gas/propane valve attached to the manifold, the manifold, the draft inducer fan, the burners and some wiring. And possibly some other components I was unable to identify.

The only defect I can see on this unit is some rust in the bottom right of the chamber here. This is a high-efficiency unit which produces condensate and it appears some of that condensate is not being drained properly.

I would recommend having the unit looked at by a professional HVAC technician to see how we can address that rusting problem. I also would recommend checking the air filter(s) every month and maintenance by an HVAC technician annually.

If I am wrong or misinformed about anything please let me know. I’m a new inspector still learning.

Josh Cockerham

The two articles I chose to write an essay on as part of the requirement for this course were “Central Air-Conditioning System Inspection” and “Gravity Furnace Inspection.”

In the first article mentioned, Nick Gromicko mentions some helpful tips for homeowners about maintaining your air conditioning unit and offers some do-it-yourself advice. He tells readers to clean the outdoor condenser unit, inspect the condensate drain line, clean the air filter, cover the exterior unit and close the air distribution registers in the winter months when cooling is not needed.

In the second article Mr. Gromicko inspects an old fashioned gravity furnace. This style of furnace is still in use in some older homes today and uses the basic principle that hot air weighs less than cold air and rises. There are few advantages to this system such as less noise and more longevity, but they are far outweighed by the disadvantages compared to today’s modern, forced warm-air heating systems. These gravity warm-air systems are much less efficient than forced warm-air systems which also makes them much more expensive to run. They also have a slow response time which is dependent upon the temperature in the house. The colder the air in the house, the faster it will heat up, but if you’re just looking to heat up the house by a few degrees, it may take this system a while. There are also other disadvantages such as asbestos, greenhouse gases, no air conditioning, oversized ductwork and carbon monoxide in the air supply.

Despite their limitations, gravity style furnaces do not need to be replaced if they are still functional. However it may be recommended that the home be updated to a modern and much more efficient forced warm-air heating system.

These pictures are from a condo Inspected last week. I had the HVAC equipment running for about 45 min and it just could not obtain the correct temperature split. I went up to the roof and found the condensing unit covered in pigeon feathers and bird droppings. The disconnect cover was missing and the insulation on the suction lines was also completely eroded away. I opened up the air handler and inspected the filter element and found that it was the wrong size and not properly installed. Since it was a heat pump type of system I tried to operate it in heat mode but it just would not produce any heat. I called it out for a complete evaluation for the obvious reasons in the photos. After seeing the condition of the units up on the roof it made me realize how important regular service is for HVAC equipment because if you let it go too long its going t cost you big bucks.

This class was probably one of the best classes that I have taken so far. It was leaps and bounds better than the training I received from my training I received at my state mandated diploma mill. Thanks Ben and Nick!

You’re welcome, Jeremy. I thought you’d enjoy: Find the Crack in the Heat Exchanger with Ben Gromicko - InterNACHI®

Here I observed a typical forced air home furnace, installed in the basement area of the home it has an attached humidifier, outside temperature was 84 degrees, compressor and air handler unit appear to be functioning normally. Unit manufacture date is 03/2001, unit is 14 years old. While unit is clean and appears to function correctly, I would recommend that a qualified heating and air contractor inspect unit to insure correct operation.

Here I observed a typical forced air home furnace, installed in the basement area of the home it has an attached humidifier, outside temperature was 84 degrees, compressor and air handler unit appear to be functioning normally. Unit manufacture date is 03/2001, unit is 14 years old. While unit is clean and appears to function correctly, I would recommend that a qualified heating and air contractor inspect unit to insure correct operation.

[ATTACH] a/c[/ATTACH]the evaporator. Everything here looks good, all lines are insulated showing no signs of dents or damage. the return filter is in place, this system also has an automatic shut off in the drain pan line. If the line becomes plugged and backs up a float switch is activated, shutting the system down. Queston. Does the freon filter ever need to be changed?

this unit is closing in on its last year or two of service. you can see the rust around the cabinet its dated 1998 and its a 10 seer. actually its amazing that its still running well

being its over 15years old and in costal fl. inside the coils are clean and has a clean air filter also good airflow.A properly functioning unit for now.

the article on asbestos didnt say much except leave it alone. which is the best bet

for most people. Is there an asbestos tester that we can buy that will tell us what we are dealing with right in the field? that would be nice rather than sending a sample to a lab.

Took the course and found to be very informative. Good information on many types of heating and cooling systems

I just finished the HVAC course and I have to say I was impressed with the amount of information. I thought I knew a lot about furnaces but I learned quite a bit. It’s definitely easier to inspect for defects when you know how devices operate.

I inspected a gas fired, forced air furnace made by Armstrong Air. The heating system was in generally good condition. The recommendations I would make would be to replace the humidifier filter and have the furnace serviced on a regular basis.

This picture is from a recent inspection I performed. There are multiple issues shown here. One issue is that the vent connection leaving the furnace is tapered to increase in size as it exits the furnace. This should be the same size as the vent connection on the furnace. Another issue is the hole (~1/2" in diameter) in the vent connector that could allow flue gasses to enter the home.

This first article I chose to read was “Inspecting Furnaces”. In this article they talk about the SOP requirements for furnace inspection and description. They give six attributed that can be used to describe a furnace. They are fuel type, distribution, air flow, gravity or forced, efficiency, and ignition. The second article I read is “Geothermal Heating & Cooling Systems”. This article explains what geothermal heating is, how it works, the types of systems, costs, and benefits of them. It discusses the types and function of the systems just like the course did. It does give some idea of the cost of installing a system however which can be considerably higher than that of installing a traditional forced air system.