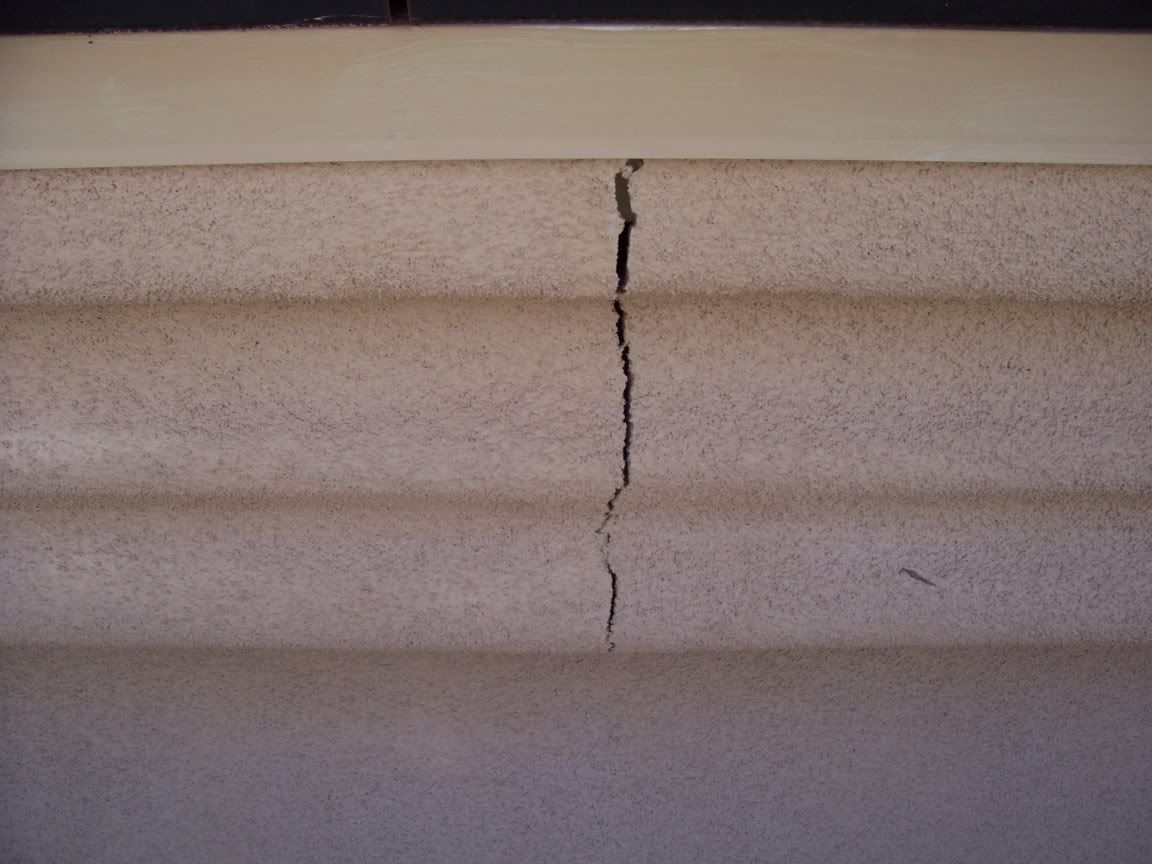

The styrofoam trim is generally a typical failure item. The weight of the cement tiles on the eaves cracked the finish everywhere from a little settlement and shrinkage of the framing.

Huge Picture!

I’m having a problem inserting small photos, oh well.

Buy a smaller camera!

Don’t feel bad, I haven’t figured out how to post any picture.

Your doing good. When you master it let me know how you did it. ha. ha.

Marcel

The ridges and the fact that they’re pretty consistent both in ridge spacing and in their distribution from top to bottom sure makes it look like some kind of expansion problem, and that would point to moisture. Ridges are mostly vertical too, whatever that means.

If it were an OSB problem the panel joints should be visible because the edges of the panels would expand more than the rest since they’re the first to wick up moisture.

This is what happens when you substitute cardboard for a proper membrane behind the stucco.

What is the proper membrane to be used behind stucco?

Follow up. Can you believe the lies?

Madness.

OK, OK. Seems to depend on who you talk to. I hear it’s 2 layers of vapor-permeable membrane like tyvek with wrinkles or built-in channels designed to allow moisture to enter the wall near the top, be pushed down by gravity between the 2 layers and exit the wall at the bottom.

I’m not sure how the moisture knows to choose the path between sheets of barrier rather than taking the path between the outer sheet and the exterior wall covering or the inner path between the inner sheet and the exterior wall sheathing.

Ive never seen a detail on this system, only read descriptions, so there’s probably a key installation detail at the top of the wall that channels moisture.

ASTM calls for 2 layers of grade-D or better. The biggest 2 problems with tyvek are

- They want all the horizontal joints taped and that can and will trap in moisture.

- They want the flashing taped back to the tyvk instead of cutting the tyvek and pulling it over the flashing.

With that said it does not matter what kind you use or how good a job putting on the moisture barrier on is done. If the windows and flashing are not installed properly and all componets in a shiplap fashion,water will either get in,or be trapped in the wall cavity.

ASTM,AAMA,Dupont all need to rethink some instalation instructions.

All the flashing tape in the world will never replace properly installed z-bar flashing for kicking

water to the outside of a wall assembly. Imo

As they keep putting the stucco on thinner and thinner {onecote} The moisture barriers and flashing details become even more improtant. Let alone the houses are built so tight evertime the HVAC kicks on it creates a vacum and even a pin hole will let in alot of water.

Examples of tyvek/moisture barrier behind the flashing.

http://www.badstucco.com/tybad/tybad.htm

http://www.badstucco.com/housewrap/HOUSEWRAP.htm

http://www.badstucco.com/windows/WINDOWS.htm

More junk mixed pictures.

http://www.badstucco.com/unassigned/unassugned.htm

Non of this stuff can be seen by the time a HI comes out to inspect the property.

Defects some before the stucco contractor got there and some while he was there. But for most HI they would have no reason to suspect such damage. The bulk of the problems window installation,flashing,moisture barrier. At the time the house was 6 - 7 years old.

shudder